Welcome to our article on boosting industrial energy efficiency! In today’s fast-paced world, industries are constantly seeking ways to optimize their operations while reducing costs and environmental impact. Industrial energy efficiency is a crucial aspect of achieving these goals. By adopting smart solutions and sustainable practices, industries can significantly enhance their energy efficiency, reduce waste and costs, and contribute to a better future.

In this article, we will explore the various aspects of industrial energy efficiency and provide insights on the strategies and technologies that can help industries improve their energy performance. We will discuss the role of energy management systems, energy audits, energy-efficient technology, green manufacturing, and effective energy management solutions in achieving industrial energy efficiency. Lastly, we will highlight the benefits of energy efficiency measures and the positive impact they can have on the environment and industry as a whole.

Key Takeaways:

- Industrial energy efficiency is crucial for reducing costs and environmental impact.

- Smart solutions and sustainable practices can significantly enhance energy performance.

- Energy management systems, energy audits, and energy-efficient technology are key to achieving industrial energy efficiency.

- Green manufacturing and effective energy management solutions are also important considerations.

- Adopting energy efficiency measures can offer significant benefits to industries and the environment.

Understanding Industrial Energy Efficiency

Industrial energy efficiency relates to the optimization of energy consumption in industrial processes. It is achieved through various energy conservation measures and the implementation of energy management systems. A focus on energy efficiency is critical for the growth of sustainable industries and for reducing the global carbon footprint.

Role of Energy Management Systems (EMS)

Energy management systems play a vital role in improving industrial energy efficiency. They allow industries to monitor, analyze and control energy consumption in their process to minimize waste and enhance overall efficiency. Energy management systems provide real-time data and reports for effective decision-making, enabling industries to identify areas of energy waste and implement corrective actions.

Energy Conservation Measures (ECMs)

Various energy conservation measures can be employed to optimize energy consumption in industrial processes. These measures include upgrading equipment to more energy-efficient models, improving insulation, and optimizing lighting and heating systems. Implementing ECMs leads to significant energy savings, reduced costs, and improved industrial sustainability.

Overall, understanding industrial energy efficiency is crucial for achieving sustainable industrial growth and reducing the carbon footprint. Energy management systems and energy conservation measures play a central role in optimizing energy consumption in industrial processes.

Conducting Energy Audits for Efficiency

Conducting energy audits is a crucial step in identifying areas for improvement in industrial energy efficiency. Energy audits involve analyzing energy consumption and identifying opportunities to reduce waste.

By conducting energy audits, industries can gain insights into their current energy consumption patterns and make informed decisions on how to optimize energy usage. Energy audits can lead to substantial energy savings and ultimately contribute to sustainable practices in industrial processes.

Embracing Energy Efficiency Technology

The 21st century has witnessed tremendous technological advancements, and this has impacted the industrial sector positively. As industries seek to attain optimal energy efficiency, there has been a renewed focus on energy-efficient technologies. These technologies help in reducing energy consumption and costs while promoting a sustainable environment.

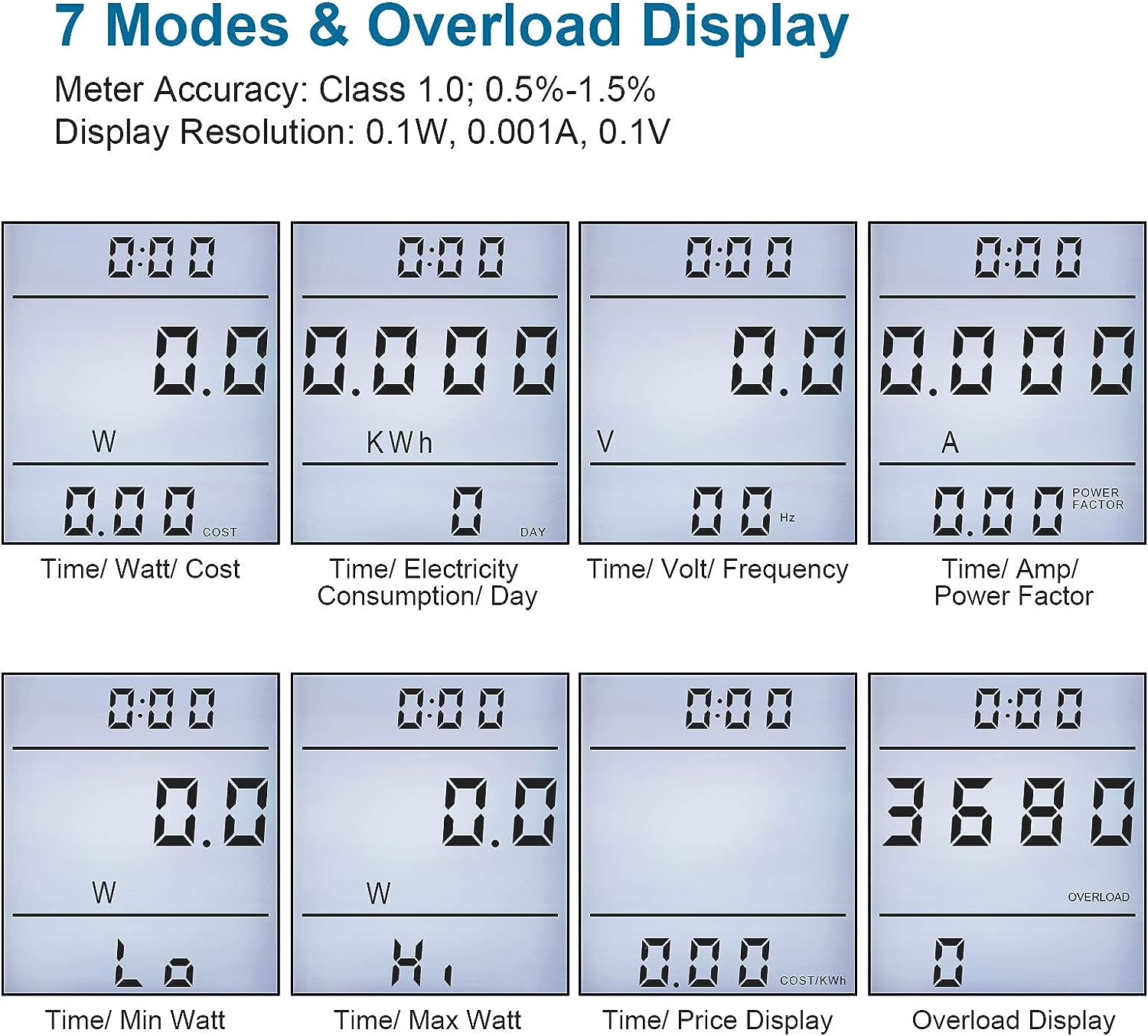

One of the most notable energy efficiency technologies is the sensor technology. Sensors can detect and monitor various industrial processes, providing data on energy usage. This data can be analyzed, and corrective measures can be taken to reduce energy consumption. Additionally, the use of smart meters, artificial intelligence, and machine learning has helped industries to optimize energy usage and reduce energy waste, leading to substantial savings in energy costs.

Another notable energy efficiency technology is the use of renewable energy. The utilization of solar panels, wind turbines, and geothermal energy has enabled industries to reduce their dependency on fossil fuels, which are costly and harmful to the environment. By investing in renewable energy sources, industries can promote sustainable energy solutions, reduce their carbon footprint, and contribute to a better environment.

Moreover, the use of energy-efficient equipment has become a significant factor in achieving industrial energy optimization. Industrial equipment that utilizes energy-efficient motors, pumps, compressors, and lighting systems can drastically reduce energy consumption while maintaining efficiency. The adoption of variable frequency drives (VFDs) in industrial processes also helps to reduce energy consumption by adjusting the power output to match the operational demands.

Industries that embrace energy efficiency technologies not only reduce energy consumption and protect the environment, but also increase their bottom line. By reducing the costs associated with energy consumption, industries can invest in other areas that promote growth and sustainability.

Implementing Energy-Efficient Practices

Improving industrial energy efficiency is not just about implementing new technologies; it is also about adopting sustainable practices. By optimizing energy consumption and reducing waste, industries can make a significant impact on their energy bills and the environment. Here are some practical strategies to implement energy-efficient practices in industrial processes.

1. Regular Maintenance of Equipment

Regular maintenance of industrial equipment is essential to ensure maximum efficiency and prevent unnecessary energy consumption. Scheduled maintenance checks can help detect any issues and repair them before they become more significant problems. Regular cleaning of equipment and replacing worn-out parts can also help reduce energy consumption and enhance overall equipment performance.

2. Energy Management

Effective energy management involves monitoring, controlling, and optimizing energy consumption in industrial facilities. By implementing energy management systems, industries can track their energy consumption and identify areas of improvement, optimize equipment performance, and reduce energy waste. Additionally, monitoring energy consumption can help identify peak energy usage times and help in energy conservation.

3. Use of Renewable Energy

Industrial facilities can reduce their reliance on traditional sources and integrate renewable energy options to reduce their carbon footprint. Renewable energy sources such as solar and wind can help meet their energy needs while reducing greenhouse gas emissions.

4. Employee Training

Employee training is essential to ensure that all staff understands the importance of energy-efficient practices. Providing regular training sessions on energy conservation and reinforcing sustainable practices can help reduce energy waste and encourage staff to be mindful of their energy consumption.

5. Efficient Lighting Systems

Replacing traditional lighting systems with energy-efficient lighting options such as LED can help reduce energy consumption and save money. Additionally, installing motion sensors to control lighting in areas where activity is low can further reduce energy usage and costs.

Implementing energy-efficient practices can help industries reduce their carbon footprint, save money, and enhance their overall sustainability. By adopting a proactive approach to energy management, industries can optimize their energy consumption, reduce waste and contribute towards building a more sustainable future.

The Role of Green Manufacturing

Green manufacturing has emerged as a pivotal force in promoting industrial energy efficiency. By adopting sustainable practices and reducing their carbon footprint, industries can significantly improve their energy efficiency, thereby contributing to a greener ecosystem.

One way in which industries can embrace green manufacturing is by minimizing their use of raw materials and reducing the amount of waste generated during production processes. By implementing measures such as recycling and reusing materials, industries can conserve energy and minimize their impact on the environment.

| Benefits of Green Manufacturing: | |

|---|---|

| Reduction in Energy Consumption: By adopting sustainable practices, industries can reduce their energy consumption, leading to significant cost savings and a lower carbon footprint. | Economic Advantages: Industries that embrace green manufacturing can benefit from tax credits, grants, and other incentives offered by governments and environmental organizations. These benefits can help offset the costs of implementing energy-efficient technologies and practices. |

| Improved Corporate Image: Industries that prioritize sustainability and energy efficiency are viewed more favorably by customers and investors. By promoting their commitment to green manufacturing, industries can enhance their brand reputation and attract environmentally conscious consumers and investors. | Long-term Sustainability: Green manufacturing measures are inherently sustainable, as they reduce waste and conserve energy, thereby promoting long-term sustainability. By considering the environmental impact of their operations, industries can create a sustainable future for generations to come. |

By embracing green manufacturing and reducing their carbon footprint, industries can not only improve their energy efficiency but also contribute to a sustainable future. With the right mix of sustainable practices and advanced technologies, industries can achieve significant energy savings and promote a cleaner, greener ecosystem.

The Role of Effective Energy Management Solutions in Boosting Industrial Energy Efficiency

Improving industrial energy efficiency requires more than just adopting sustainable practices. It requires the implementation of effective energy management solutions. With energy consumption being a significant operating cost for many industries, effective energy management can lead to noticeable cost savings while also reducing the overall carbon footprint.

One of the key ways of achieving effective energy management is by investing in energy-efficient equipment. By replacing outdated or inefficient machines with newer, more energy-efficient models, industries can significantly reduce their energy consumption. Additionally, utilizing energy-saving technologies such as LED lighting, smart thermostats, and programmable controllers can help optimize energy consumption in industrial settings.

| Benefits of Effective Energy Management Solutions: |

|---|

| 1. Reduced Energy Consumption: Effective energy management solutions can help industries reduce their energy consumption, leading to significant cost savings and a reduced carbon footprint. |

| 2. Improved Process Efficiency: By optimizing energy consumption in industrial processes, industries can achieve improved process efficiency, resulting in higher productivity and reduced downtime. |

| 3. Increased Operational Efficiency: Effective energy management solutions can also lead to increased operational efficiency by identifying areas of improvement and implementing energy-saving measures. |

| 4. Enhanced Sustainability: By reducing energy consumption and carbon emissions, effective energy management solutions contribute to a more sustainable future. |

Overall, effective energy management solutions are crucial for boosting industrial energy efficiency. By investing in energy-efficient equipment and technologies, industries can reduce their energy consumption, achieve higher productivity, and move towards a more sustainable future.

The Benefits of Energy Efficiency Measures

Implementing energy efficiency measures in industrial settings brings numerous benefits that go beyond just saving on energy bills. By reducing energy consumption, industries can significantly decrease their carbon footprint, making a positive impact on the environment. Moreover, it promotes sustainable energy practices that are vital for a better, cleaner future.

One of the main advantages of energy efficiency measures is the cost savings they offer. By optimizing energy consumption, industries can avoid unnecessary expenses on energy bills, enabling them to allocate resources to other important areas of their business. Furthermore, energy-efficient equipment and technologies are known to have a longer life span, reducing maintenance and replacement costs, which can be a significant advantage in the long term.

“By reducing energy consumption, industries can significantly decrease their carbon footprint, making a positive impact on the environment.”

Adopting energy-efficient practices can also improve the overall health and well-being of the workforce. By reducing energy consumption, industries can reduce their greenhouse gas emissions, leading to better air quality and reducing the risk of respiratory illnesses and other health problems. Additionally, energy-efficient equipment produces less noise pollution, creating a quieter, more pleasant working environment.

Another advantage of embracing energy efficiency measures is that it can improve a company’s reputation and brand image. As the emphasis on environmental sustainability increases, industries that prioritize energy efficiency and sustainable practices are perceived as responsible and forward-thinking. This can lead to increased customer loyalty, attracting environmentally conscious consumers, and creating a competitive advantage in the market.

In conclusion, while the initial investment in energy efficiency measures may seem costly, the long-term benefits are significant. By reducing energy consumption, industries can achieve cost savings, improve workforce health and well-being, enhance brand reputation, and most importantly, contribute to a sustainable future.

Conclusion

Improving industrial energy efficiency is imperative for a sustainable future. From understanding energy management systems to embracing energy efficiency technology and implementing energy-efficient practices, there are various ways in which industries can promote sustainable energy practices and reduce their carbon footprint.

By conducting energy audits and implementing effective energy management solutions, industries can achieve substantial energy savings and improve overall efficiency in their processes. Investing in energy-efficient equipment and adopting green manufacturing practices are also crucial steps towards achieving industrial energy efficiency and reducing energy consumption.

The benefits of energy efficiency measures are numerous, including significant cost savings, reduced industrial carbon footprint, and a positive impact on the environment. Moving towards a sustainable future requires a collective effort, and the industrial sector has a significant role to play in achieving this goal.

FAQ

What is industrial energy efficiency?

Industrial energy efficiency refers to the optimization of energy consumption in industrial processes to achieve maximum efficiency and reduce energy waste.

Why is industrial energy efficiency important?

Industrial energy efficiency is important because it leads to cost savings, reduced carbon emissions, and improved sustainability. It also helps businesses remain competitive in a rapidly evolving energy landscape.

What are smart solutions for industrial energy efficiency?

Smart solutions for industrial energy efficiency include the use of advanced energy management systems, automation technologies, and data analytics to optimize energy consumption and identify areas for improvement.

What are energy conservation measures?

Energy conservation measures are actions taken to reduce energy consumption and improve efficiency. Examples include upgrading equipment, implementing proper insulation, and adopting energy-efficient lighting systems.

What is an energy audit?

An energy audit is a systematic evaluation of energy usage in a facility or process. It helps identify areas where energy efficiency can be improved and suggests strategies for reducing energy consumption.

How can energy audits benefit industrial processes?

Energy audits can benefit industrial processes by identifying energy-saving opportunities, reducing operating costs, improving productivity, and promoting sustainability.

What are energy-efficient technologies?

Energy-efficient technologies refer to equipment, systems, and processes designed to minimize energy consumption while maintaining or enhancing performance. Examples include high-efficiency motors, LED lighting, and advanced control systems.

How can industries implement energy-efficient practices?

Industries can implement energy-efficient practices by adopting measures such as optimizing production processes, improving insulation, training employees on energy conservation, and regularly monitoring and maintaining equipment.

What is green manufacturing?

Green manufacturing refers to the implementation of environmentally sustainable practices in the manufacturing process. It focuses on reducing waste, conserving resources, and minimizing the overall environmental impact.

How can energy management solutions help reduce industrial energy consumption?

Energy management solutions, such as real-time monitoring, energy analytics, and demand response systems, provide insights into energy usage patterns and help identify opportunities for energy savings and efficiency improvements.

What are the benefits of energy efficiency measures in the industrial sector?

Energy efficiency measures in the industrial sector offer benefits such as cost savings, reduced greenhouse gas emissions, compliance with regulations, improved operational efficiency, and enhanced corporate social responsibility.